Palm kernel shell charcoal machine produced by Beston Group has stood out from the competition in the international market and obtained a better reputation in recent years. The machine can realize the purpose of turning waste into treasure. Through a series of deep process, the palm shell can be turned into various useful materials such as charcoal, combustible gas, tar and wood vinegar. Each of the end products has great utilization value, that’s why Beston palm shell charcoal machine could be so popular in the whole industry.

Beston palm kernel shell charcoal making machinery possesses some attractive features, including high working efficiency, high production yield, excellent security design, remarkable sales performance, unique carbonizer design, etc.

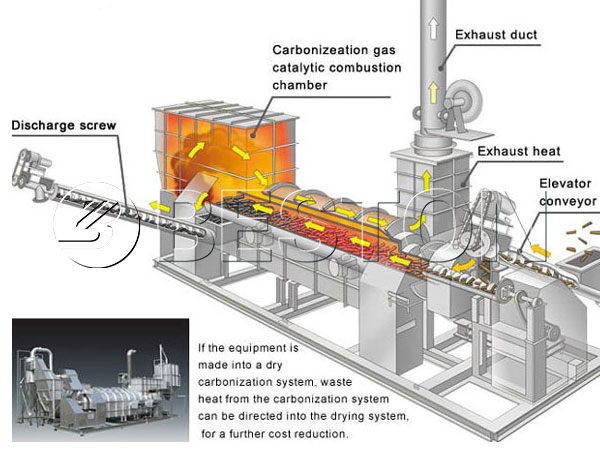

Unique structure and design of palm kernel shell charcoal machine

Making charcoal from palm shell will pass through a series of process including high temperature carbonization, smoke discharge, sulphur emission and charcoal enrichment. Each part of palm shell charcoal machine has a well cohesion and coherence, so as to make sure that the machine can work smoothly. In addition, the palm shell carbonization furnace has introduced double-layer design, which can highly increase the working efficiency and heat utilization efficiency. The machine mainly uses the hot air as heat source which will not contact with the bottom of furnace directly to extend the service life of reactor. The rational structure design of the charcoal machine plays an important role in the quality of end products. The economic values of the final products produced by Beston palm kernel shell carbonization plant are obvious, which will get your cost back soon and create great profit for you.

Applications of palm kernel shell charcoal

The charcoal from palm shell can be widely used as fuel in the area of living life, industry and agriculture. In addition to the palm shell charcoal, the combustible gas, tar and wood vinegar are also important final products. As the demand of these final products are becoming bigger and bigger, the marketing prospect of the palm shell charcoal carbonization machine has become brighter and brighter.

| End Products | Area | Usage |

| Charcoal | Daily life | * widely used as fuel in BBQ. |

| * used as fuel in other area. | ||

| Agriculture | * attach heavy metal to improve the quality of soil. | |

| Industry | * can be reprocessed into activated carbon. | |

| * used for construction bricks with clay. | ||

| * widely used as fuel in industries such as steel and iron factories, ceramics, etc. | ||

| Gas | Daily life | * widely used as fuel. |

| Agriculture | * greenhouse agriculture heating. | |

| Industry | * used as fuel for heating or drying. | |

| * can be used for generator to get electricity. | ||

| Wood vinegar, tar | Industry | * belongs to high temperature resistant and waterproof, the great materials in shipbuilding and paint industry. |

| * used as raw materials in chemical and medicine. | ||

| Agriculture | * used as plant nutrition regulates auxin or insecticide. |

Security design of Beston palm shell charcoal machine for sale

1. The design of PLC control system: this kind of system can make the whole production line more intelligent, and also decline the labor intensity to increase the working efficiency.

2. We have installed the automatic display device of temperature, pressure and alarm apparatus.

3. The surface of the carbonizing furnace is covered by casing, which can avoid the heat losing and scalding workers.

4. The palm kernel shell charcoal making machine is also equipped with professional dedusting system, and the whole process can meet international emission standard.

5. The whole palm kernel shell carbonization process is running in the fully sealed condition, which can reduce the occurring rate of hide dangers.

In recent years, our palm kernel shell charcoal machine has been exported to 10+ countries, which has given us rich experience in carbonization field. Our machine can meet the public demand no matter in technology or quality. Welcome to Beston Group!

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||