Since the invention, Beston coconut shell charcoal making machine for sale has been sold well in Southeast Asia market. As we know that Southeast Asia is rich in coconut, and how to dispose coconut shell is an issue in local. Through the process of converting coconut shell to charcoal, Beston coconut charcoal making machine can not only solve the pollution problem, but also can drive the development of local economy. In addition to coconut shell, the charcoal maker machine can also process other biomass materials, such as palm shell, wood, leaves , etc.

Working process of charcoal shell charcoal making machine

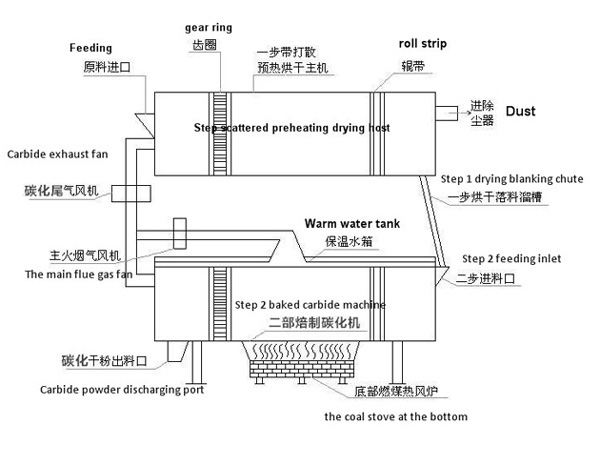

Base on the coconut shell charcoal manufacturing method, Beston has developed coconut shell charcoal machinery for sale, which is equipped with double layers furnace, condenser system, dedusting machine, cooling system, draft fan and so on. The following is the information on how to make coconut shell charcoal.

At first, according to the stipulation, we should install a crusher and dryer as pretreatment devices, which can crack raw material into small pieces whose size should be less than 50 mm and guarantee the moisture of coconut shell is lower than 20%;

Next is the most important step in the whole coconut shell charcoal manufacturing process, the cracked and dried coconut shell will be delivered into coconut shell carbonization furnace by belt conveyor and heated by high temperature. When it reaches the specific temperature, the coconut shell in the furnace will generate combustible gas and charcoal.

Then the charcoal from coconut shell will pass through cooling system to decline the temperature of charcoal to less than 30℃, and after that the coconut shell charcoal will be collected directly; as for the combustible gas, it has played an important role in the whole production process. The combustible gas will be recycled to heat furnace after purified by spray dedusting system, which can not only save more traditional fuel but also can protect environment, and moreover, the whole coconut shell charcoal making process has no pollution, so as to achieve the green production.

Final products of coconut shell charcoal making machine

Coconut shell always can be convert to coconut shell charcoal, combustible gas, tar and wood vinegar through coconut shell production process. These four kinds of materials can create higher economic benefits, which will get your charcoal making machine cost back soon.

| End Products | Area | Usage |

| Charcoal | Daily life | * widely used as fuel in BBQ. |

| * used as fuel in other area. | ||

| Agriculture | * attach heavy metal to improve the quality of soil. | |

| Industry | * can be reprocessed into activated carbon. | |

| * used for construction bricks with clay. | ||

| * widely used as fuel in industries such as steel and iron factories, ceramics, etc. | ||

| Gas | Daily life | * widely used as fuel. |

| Agriculture | * greenhouse agriculture heating. | |

| Industry | * used as fuel for heating or drying. | |

| * can be used for generator to get electricity. | ||

| Wood vinegar, tar | Industry | * belongs to high temperature resistant and waterproof, the great materials in shipbuilding and paint industry. |

| * used as raw materials in chemical and medicine. | ||

| Agriculture | * used as plant nutrition regulates auxin or insecticide. |

High working efficiency of coconut shell charcoal production plant

1. Our coconut charcoal production equipment has a unique design on the furnace, which has introduced double-layer design to highly increase the efficiency of heat utilization from the beginning, and in this way, the production yield of the whole production line also raises.

2. Besides, each part of the coconut shell charcoal making machine has a close connection, which can guarantee the consistency of the whole operation; the machine has also achieved fully continuous production, and the machine can keep working 24 hours without a stop, so the working efficiency can be imaged.

3. The fully sealed working condition can avoid heat losing and guarantee enough heat source, which is also helpful to raise carbonization efficiency.

4. Meanwhile, the charcoal from coconut shell is the best additive to produce activated carbon. If you want to have a further process to the coconut charcoal, Beston Machinery can also provide you with related forming machines which can increase the marketing value of the charcoal.

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||

Finally, we hope that these information of Beston coconut shell charcoal making machine for sale can help you a lot, and if you want to have a deep understanding to our products, please leave you detail massages or contact Beston on Facebook:

What material do you want to process?

What handing capacities do you expect?

What’s your name, and you useful phone number or email address?