Sewage sludge is quite common in waterworks, living water and industrial waste waster treatment plant, which has contained higher poisonous and harmful substance. If not disposed with right methods, it will cause serious soil pollution and air pollution. So in many countries, many manufacturers have developed sewage sludge treatment plant to produce charcoal through carbonization technology, which can not only efficiently solve the serious pollution problem, but also make great contribution to the local economy.

Beston sewage sludge treatment carbonization plant has higher carbonization efficiency, appropriated carbonization time and uniform distribution of temperature, which can efficiently guarantee the quality of end products. This technology has been widely used both at home and abroad, and it is also a mainstream technology for sewage sludge treatment and disposal recommended by many countries.

Carbonization process requirement on Beston sewage sludge treatment plant

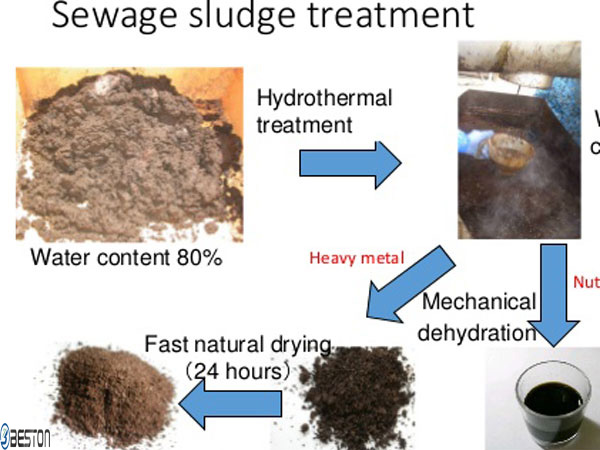

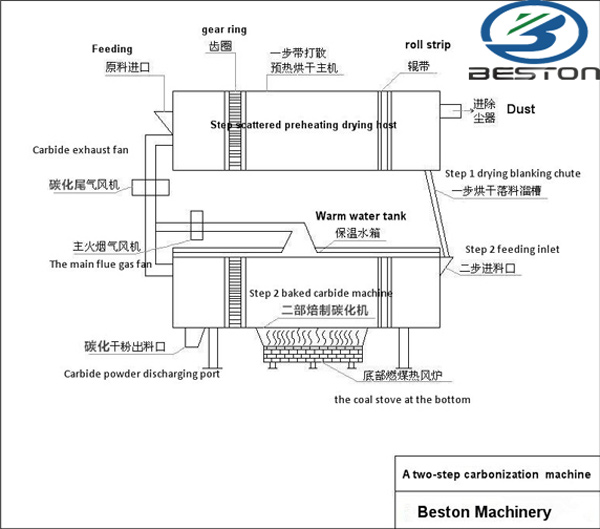

Beston sewage sludge disposal plant mainly includes four major steps to finish the whole carbonization process, high temperature pyrolysis, smoke emission, sulfur release and charcoal enrichment. During the entire carbonization process, we will control the moisture of raw material less than 20% , and the temperature of carbonizing furnace is between 650℃ and 780℃. The high temperature pyrolysis will make the sludge generate neutral reaction to produce charcoal and combustible gas. Then through the cooling system, the temperature of hot charcoal is reduced to 30℃, which will be safer for collecting. As for the combustible gas, it will pass through the spay dedusting system and condenser system to form tar and wood vinegar.

Reasons why you should choose Beston sewage sludge disposal machine

Values created by sewage sludge treatment equipment

a. The carbon made from sewage sludge has become a fine alternative of all traditional fuels. Due to the higher caloric value but little pollution, the sludge charcoal has been used in many areas.

b. The whole sewage sludge carbonization process is sealed, and there is no harmful components to cause pollution. This project has responded to the international policy of environmental protection and obtained supporting from the government.

c. The sewage sludge carbonization plant is helpful to improve the local environment and promote the economic development.

Advantages of Beston sewage sludge treatment equipment for sale

a. Our carbonization machine for sale has occupied smaller floor space, which can reduce the cost and investment for customers.

b. The whole set of machine has a rational design and structure, which can raise the working efficiency and keep the carbonization process running smoothly to avoid the unnecessary errors.

c. The machine can realize fully automatic production, and it is equipped with PLC control system to make the working process more intelligent, convenient and easier to operate.

| Pre-sale Service | After-sale Service |

| 1. Technical data and competitive price provided. | 1. Supervise manufacturing to guarantee high quality. |

| 2. Factory visit and trial for you. | 2. Fast delivery, and close track on goods till you receive the good. |

| 3. Free plan for your site and project. | 3. Engineers will be sent to your site for the installation, testing and training the workers. |

| 4. Reasonable suggestion with shipping freight. | 4. Periodical call visit to make sure there is no problem of the equipment or find the problem timely and solve it immediately. |

Besides sewage sludge, the carbonization equipment is also can be used for processing municipal solid waste and biomass waste, such as fruit shell, wood dust, straw, etc. Each member of Beston Group is looking forward to receiving you message or visiting. Send email for free quotation!

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||